CEO Takaaki Yamamoto on the current COVID-19 situation

Dear business partners,

We acknowledge the difficult situations many of us are facing with the outbreak of COVID2019 virus around the world.

We, AMCON Europe, take the current situation seriously with priority on health of all stakeholders including employees, families of employees, clients, business partners, local community etc.

We therefore applied required restrictions on our business activities according to the recommendations from the specialists and the authority.

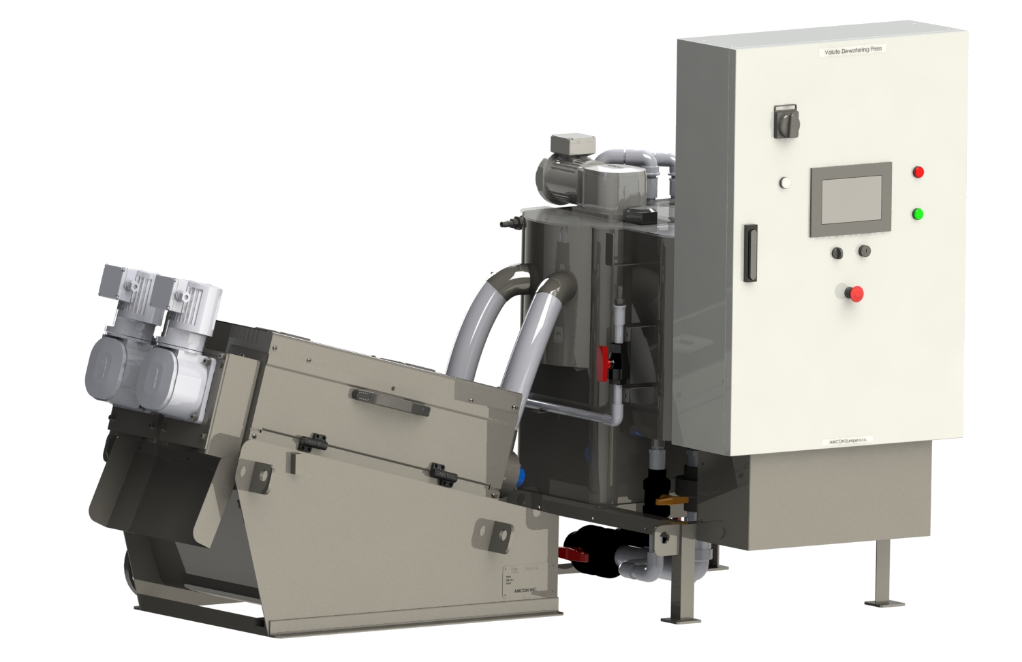

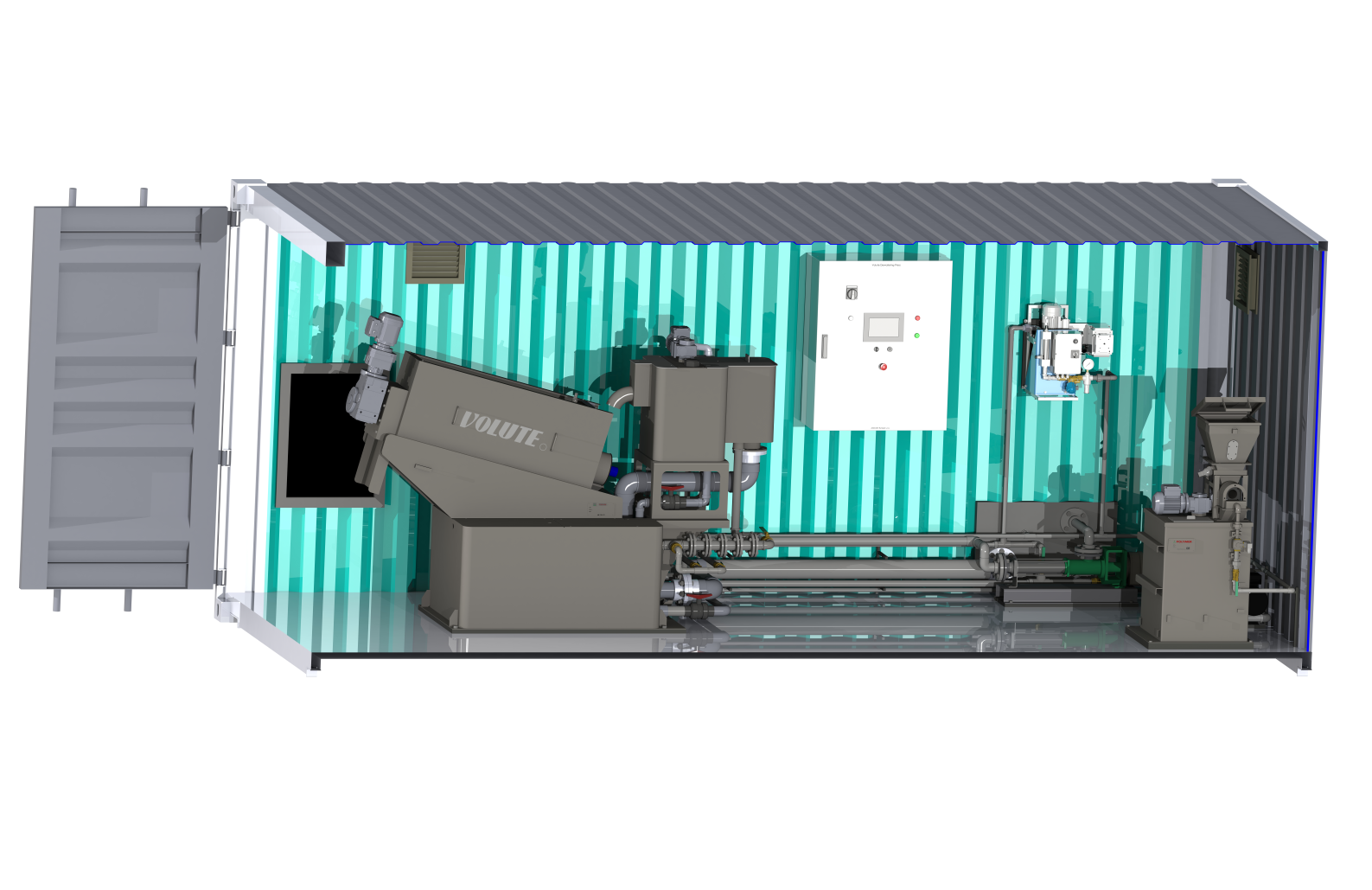

I feel proud about our products and services are contributing to the protection and improvement of hygienic conditions of our life and environment especially in these circumstances as of today, and appreciate again in this occasion all the supports given by all of the people who participate in this activity.

While we are minimizing the impacts of the restrictions on our business, please note the following potential cases that we would like to discuss individually if it applies to you.

Just to assure you, so far we have not observed any significant inconveniences caused to our business partners.

– possible delay with the delivery of already ordered products and services (due to the transport limitation, a potential legal requirement to suspend our manufacturing operation)

– potential longer delivery time of our products and services in the future

– postponement and cancellation of meetings

– proactive utilization of tele-meetings

Thank you for your understanding,

Takaaki Yamamoto

CEO

AMCON Europe s.r.o.