ADVANTAGES

Trough Conveyors ESB-SC

Reliable and versatile solution for transporting bulk materials, including dewatered sludge or other adhesive materials. Their robust design guarantees long service life under continuous operation, while the simple construction ensures low maintenance and easy adaptation to project requirements.

Tubular Screw Conveyors ESB-TC

Compact and fully enclosed conveying system designed for space- and cost-efficient transport of bulk materials. Especially suitable for powders and with the possibility of vertical transport. All the while minimizing dust and spillage.

Belt Conveyors ESB-BC

Versatile and efficient transport solution for a wide range of materials. With fully customizable length, width, and inclination, they can be tailored to your project needs while ensuring smooth, reliable, and cost-effective operation.

General Features

Energy Efficiency

Low energy consumption thanks to optimised screw design and quality electric gearboxes. Power consumption starts from just 0.55 kW for the smallest models.

Flexible Design Solutions

Choice between stationary, rotating, or mobile constructions and top- or bottom-motor mounting, according to site-specific needs. Conveyor lengths can naturally be customised. Possibility to add container-level sensors for fully automatic control of cake distribution. Possibility to choose from different types of discharge doors and inlet hoppers.

Easy Operation and Maintenance

Proven and reliable designs focussed on easy inspection, maintenance and cleaning. E.g. with external bearing housings and soft packings.

Freeze Protection

For outdoor installations, heating with self-regulating heating cable and insulation is available, ensuring trouble-free operation even during winter months.

Standard specifications of trough screw conveyors AMCON ESB-SC

| Technical data | ESB-SC-200-xx-xxx-xx | ESB-SC-225-xx-xxx-xx | ESB-SC-250-xx-xxx-xx |

|---|---|---|---|

| Max. capacity in horizontal plane (m³/hour) | 2 – 4 | 3 – 5 | 4 – 6 |

| Screw diameter (mm) | 200 | 225 | 250 |

| Screw speed (min⁻¹) | 22 – 34 | 22 – 34 | 22 – 34 |

| Conveyor length (m) | 2 – 6, per 1m | 2 – 6, per 1m | 4 – 6, per 1m |

| Total weight (kg) | 150 – 750 | 200 – 800 | 200 – 900 |

| Total installed power (kW) | 0.55 – 2.2 | 0.55 – 2.2 | 0.75 – 3.0 |

| Operating voltage (V) | 3x400V/50Hz | 3x400V/50Hz | 3x400V/50Hz |

| Electrical protection rating (-) | IP55 | IP55 | IP55 |

| Material | AISI 304 (1.4301) | AISI 304 (1.4301) | AISI 304 (1.4301) |

| Inclination | 0-35°, per 5° | 0-35°, per 5° | 0-35°, per 5° |

| Possibility of complete or partial insulation with heating | Yes | Yes | Yes |

Possible customisation

ESB-SC-200, 225, 250: any length up to 6 m. Any angle up to 40°

ESB-SC-300: any length between 2 m and 8 m. Any angle up to 40°

Material: AISI 316L (1.4404)

Manually or electrically rotatable designs

Different types of discharge doors and inlet hoppers

Standard specifications of tubular screw conveyors AMCON ESB-TC

| Technical data | ESB-TC-200-xx-xxx |

|---|---|

| Max. capacity in horizontal plane (m³/hour) | 2 – 4 |

| Screw diameter (mm) | 200 |

| Screw speed (min⁻¹) | 22 – 34 |

| Conveyor length (m) | 1.5 a 2.5 |

| Total weight (kg) | 150 – 750 |

| Total installed power (kW) | 0.55 – 2.2 |

| Operating voltage (V) | 3x400V/50Hz |

| Electrical protection rating (-) | IP55 |

| Material | AISI 304 (1.4301) |

| Inclination | 0-35°, per 5° |

| Possibility of complete or partial insulation with heating | No |

Possible customisation

ESB-TC-200: Any length up to 4 m. Any angle up to 90°

ESB-TC-225, 250: Any length up to 4 m. Any angle up to 90°

Material: AISI 316L (1.4404)

Manually or electrically rotatable designs

Different types of discharge doors and inlet hoppers

Belt Conveyors AMCON ESB-BC

ESB-BC-300, 400, 650: Any length up to 6 m. Any angle up to 40°

Material: AISI 304 (1.4301), AISI 316L (1.4404)

Manually or electrically rotatable design

Shaftless Trough Screw Conveyors AMCON ESB-FC

ESB-FC-200, 225, 250: Any length up to 6 m. Any angle up to 40°

Material: AISI 304 (1.4301), AISI 316L (1.4404)

Manually or electrically rotatable design

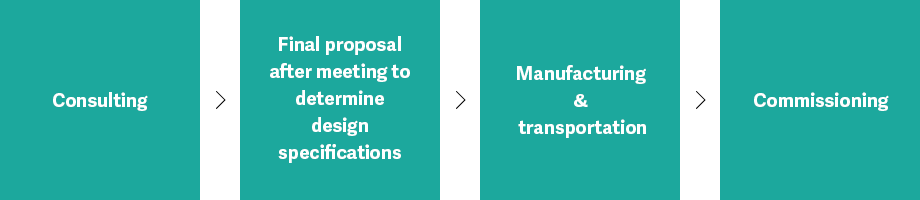

Flow for Product Installation