ADVANTAGES

AMCON has carefully selected and been periodically updating our list of the most suitable flocculants for sludge dewatering based on more than 45 years of experience. Sample products are available, and we also take sludge samples and perform the polymer matching test free of charge.

We reduce sludge production

Sludge reduction can be achieved if the right chemicals are dosed in the right amount in the right way. Throughout the history of AMCON, we have learned how to do it. Some of our coagulants do not produce surplus sludge, while metal coagulants such as ferric sulphate produce a lot of sludge. Please feel free to talk to us for an actual demonstration on your site.

YESfloc® Organic coagulants

- Safe, organic, and biodegradable coagulant made from natural organic compounds

- Reduces sludge production by up to 30% compared to metal salt coagulants such as iron sulfate, with the same efficiency of coagulation

- Lowers dosage

- Helps to increase your DAF capacity

- Does not affect pH, which eliminates necessity to use extra chemical for neutralization

- Supplied in 25kg tub or IBC tank

AMCON will demonstrate the efficiency on your existing facility.

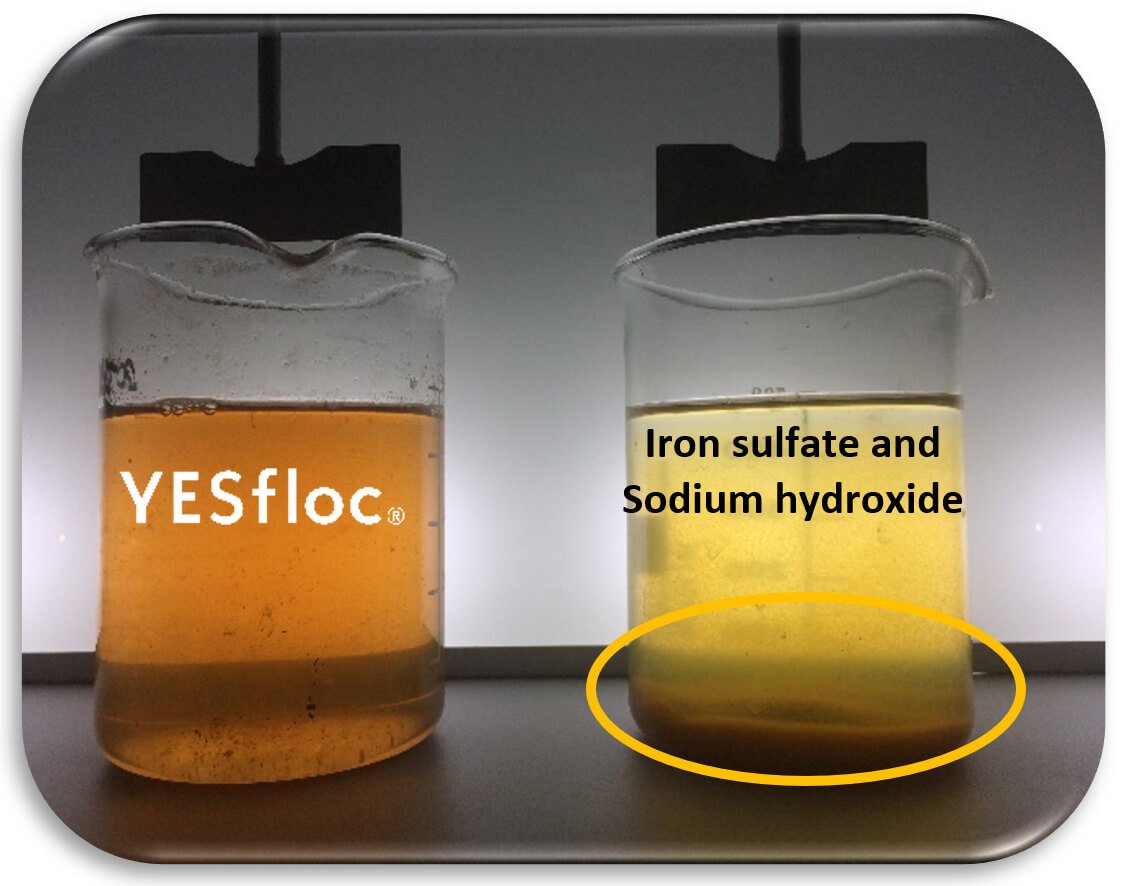

Lab Demonstration

- 3ml of YESfloc PG was dosed to tap water in the left beaker.

- 1ml of Iron sulfate (41%) and 0.7ml of Sodium hydroxide (40%) dosed to tap water in the right beaker.

Result

Sludge is produced by itself in the right beaker. Now imagine this is happening in your DAF or sedimentation process.

Wastewater Treatment Process Optimization

With our process optimization service, we are able to help you if you think:

- The final effluent quality has not been good.

- Our production volume is increasing, and the current wastewater treatment plant capacity cannot handle any more wastewater.

- Chemical cost is the biggest operation cost of the wastewater treatment, and we would like an independent professional review on our selection and dosage of chemicals.

- Reaction of chemicals with our wastewater does not seem to be good recently.

- Sludge dewatering has not been going well recently. Sludge cake is wetter.

- The sludge disposal cost has increased.

Case Studies

Dewatering raw spent wash

The Europe’s largest alcohol drink distillery located in Scotland has a great ambition to be the world’s most environmentally sustainable distillery. Their bioenergy plant generates renewable energy from spent wash (mixture of wheat, malted barley, yeast and water produced during distillation). The spent wash needs to be separated into water and the solids, but the polymer flocculant that is necessary to be used for separation can be a massive operational cost if it is not optimized well. We, however, managed to optimize the whole process from analysis of the spent wash, conditioning, flocculating, and to dewatering for the customer. After our chemical and process optimization, the bioenergy plant has been receiving quality dry spent wash as renewable biofuel. And the polymer flocculant used is of course biodegradable eco-friendly product.

Primary treatment of wastewater

The factory was expanding its production and their wastewater started breaking the discharge consent. We engineered a complete package of primary wastewater treatment using YESfloc® and AMCON’s VOLUTE™ dewatering screw press, which had been working to reduce suspended solids by 85%, fat and oil by 95%, and COD by 87%.

One of the biggest Scottish whisky distilleries

Due to the nature of spent wash, it is not easy to flocculate suspended solids in spent wash. Moreover, the distillery wanted to recycle dewatered digestate spent wash as animal feed. YESfloc® with its water based GRAS approved spec was finally the only flocculant that met these criteria and we managed to engineer a transformation of spent wash digestate to animal feed.